Robust manufacturing capabilities

Engineered Pump Division

- Located about 25 km from central Kolkata, the two facilities have ~60,000 m² of floor space.

Conventional Pump Division

- Located about 20 km from Delhi, the plant has 68,000 m² of floor space

Drainage Pump Division

- Located about 20 km from Delhi, the plant has 68,000 m² of floor space.

Captive Foundry

- Located about 21 km from Mumbai, the plant has 6,200 m² of floor space.

Engineering excellence, manufacturing capability

Engineered Pump Division

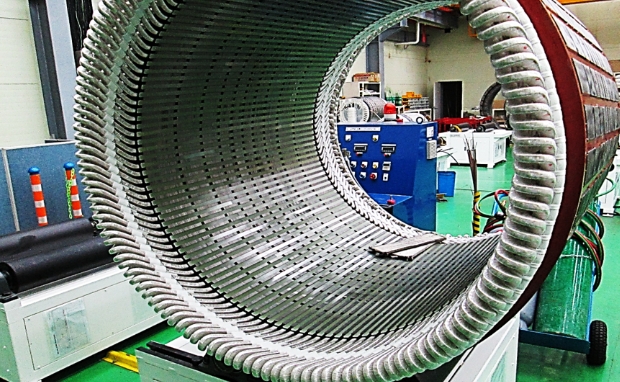

At the heart of WPIL’s large-scale pumping solutions, the Engineered Pump Division in Kolkata operates three manufacturing facilities and a cutting-edge test facility. With over five decades of experience, the division delivers robust, high-performance pumps for industrial, irrigation, and drainage applications. Backed by a world class engineering center, the division is built for scale, reliability, and precision.

High-capacity pump offerings:

- Large Vertical Pumps for all applications

- Metallic Volute Pumps for high-head irrigation

- Concrete Volute Pumps for drainage flows up to 80,000 m³/h

Engineering Capabilities:

Conventional Pump Division

WPIL’s Conventional Pumps Division offers an extensive portfolio of pumps covering the entire range of applications in municipal, irrigation and industrial segments. Backed by a modern test facility, with various data acquisition systems designed for handling multiple flows and allowing remote witness capabilities, the division ensures proven performance and reliability. It underscores WPIL’s leadership across all critical specialized applications.

Product Highlights

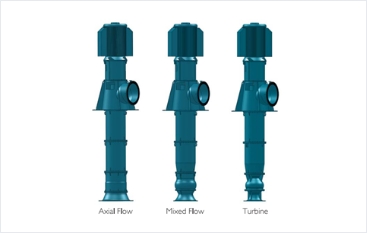

- Vertical Turbine, Mixed & Axial Flow Pumps

- Horizontal Split Case, End Suction, Non-Clog, and Multistage Pumps

- Submersible Motor Pumps

- Submersible Sea Water Lift Pumps

Engineering Capabilities:

Drainage Pump Division

The drainage division provides a comprehensive range of submersible pumps to cover various applications in dewatering, sewage, and drainage applications.

Captive Foundry

WPIL’s in-house foundry is a high-performance manufacturing hub designed to support our engineered pumps and infrastructure solutions with full control over quality, customization, and timelines. Equipped with modern technology and robust capacity, it ensures precision casting for demanding applications across sectors.

Facility Highlights:

- Modern melting capabilities with induction and arc furnaces

- Annual casting capacity of 1,500 tons, with single-piece castings up to 11 tons Material versatility: Expertise in casting iron, carbon steel, austenitic, and duplex stainless steel

- Advanced simulation: Softcast casting simulation software for optimized design and quality

- Integrated infrastructure: Site equipped with moulding section, automated sand plant, heat treatment facilities, and spectrometer

Research & Development

WPIL’s world-class manufacturing infrastructure forms the backbone of our global operations. Combining advanced engineering, modern production technologies, and stringent quality systems, we deliver reliable, high-performance solutions at scale. Our vertically integrated operations ensure complete control over quality and delivery timelines. Supported by specialized foundries and advanced testing centers, our manufacturing ecosystem is built to serve diverse industries worldwide while driving innovation and efficiency.

Our multidisciplinary teams specialize in hydraulic modeling, advanced material analysis, and system-level optimization to engineer reliable, efficient, and tailor-made pump solutions for critical applications across the globe.

Backed by continuous innovation and practical insight, the R&D centre enables WPIL to stay ahead of industry needs—delivering products that are both future-ready and field-proven.

Expertise Domains

- Hydraulic Engineering and analysis

- Mechanical Engineering

- Fluid System Design

- Smart Pump Technology

- System analysis for complex pumping stations

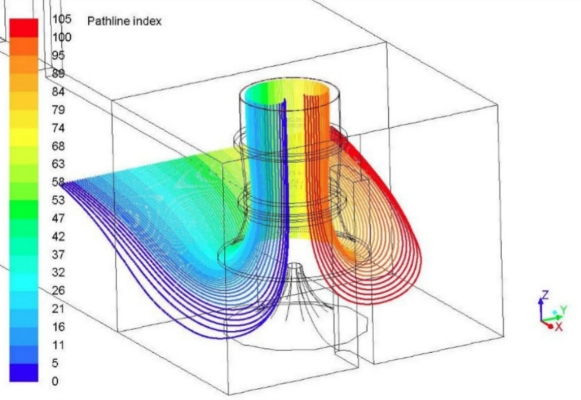

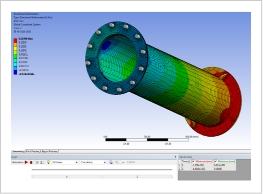

- Advanced suite for CFD analysis, 3D modeling & simulation

Dedicated FDC Centre

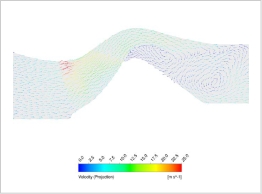

- Sump flow pattern analysis and correction

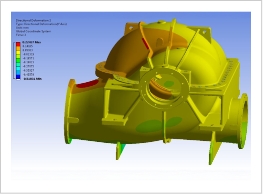

- Pump performance enhancement

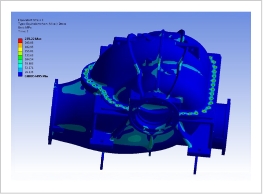

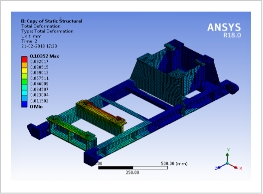

- Structural and vibration analysis

- Water hammer analysis

Specialty Technologies

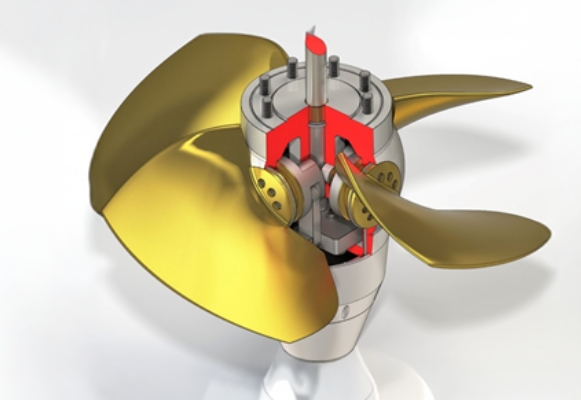

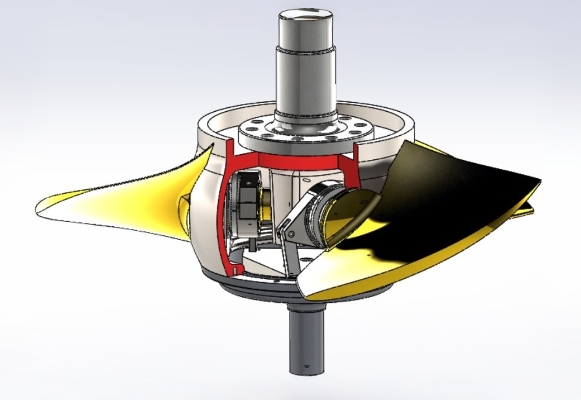

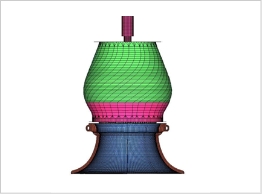

Vertical Turbine Pumps

- Hydraulics spanning radial, mixed flow, and axial flow design

- Flow capacity ranging up to 50,000 m³/hr

- Pump speed ranging from 1,500 US NS to 13,000 US NS

- Pump head ranging up to 200 m

- Mechanical configuration in rotor pullout

- High efficiency and high capacity pumps suitable for drainage, dewatering, irrigation, municipal water supply, and cooling water

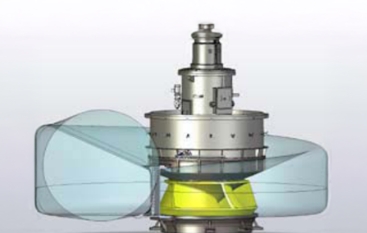

Metallic Volute Pumps

- High flow / high head pumping solutions

- Flow capacity ranging from 7,000 m³/hr to 110,000 m³/hr

- Pump head ranging from 25 m to 200 m

- Pump model is tested as per the IEC 60193 standard

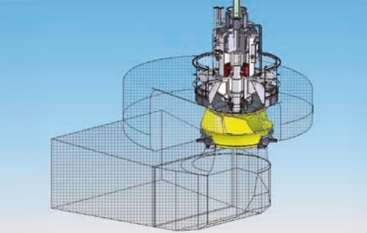

Concrete Volute Pumps

- High flow pumping solutions, so fewer pumps in system

- Flow capacity ranging up to 120,000 m³/hr

- Pump speed ranging 100 RPM to 400 RPM

- Pump casing produced in concrete in-situ

- Resistant to corrosion

- Pump model is tested as per the JIS B 8327 standard

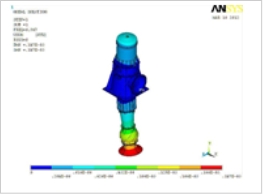

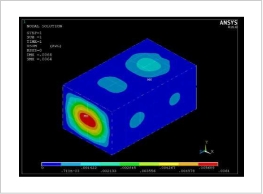

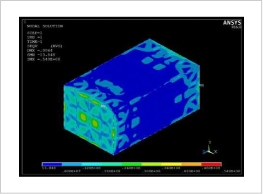

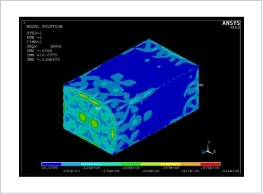

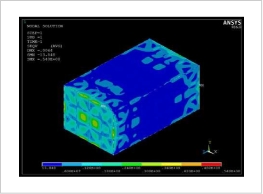

Structural analysis of 43,400 m³/h and 4.4 MW capacity vertical turbine pump using Ansys

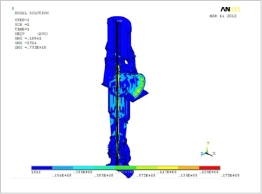

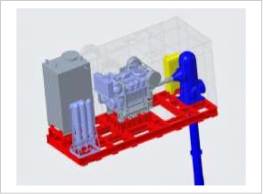

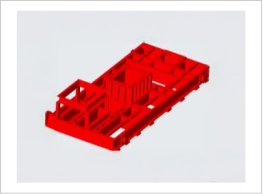

ONGC off-shore fire water pump skid structural analysis using Ansys

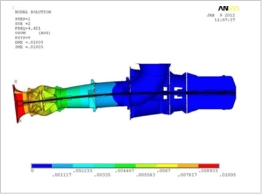

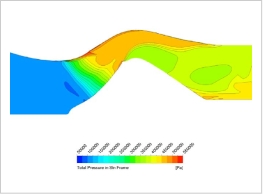

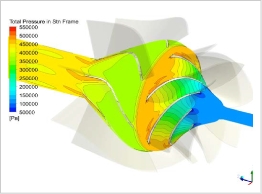

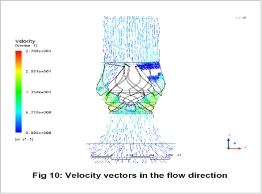

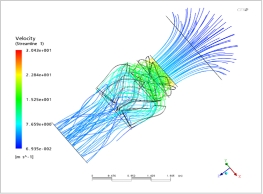

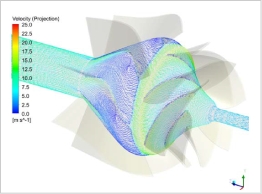

CFD analysis of flow pattern in VT pump by Ansys CFX

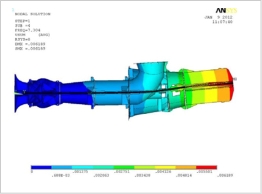

Stress analysis and structural model analysis of horizontal pumpset using Ansys

Technology & Engineering

WPIL has built its engineering expertise through joint ventures with global leaders like Johnston Pumps (USA) and Worthington Pumps, focusing on the development of vertical turbine, split case, end suction, sewage, and multistage pumps. In partnership with Hayward Tyler (UK), WPIL has also refined submersible pump designs to better meet Indian operating conditions. Furthering its innovation capabilities, the in-house R&D team has successfully developed advanced dry motor submersible pump designs.

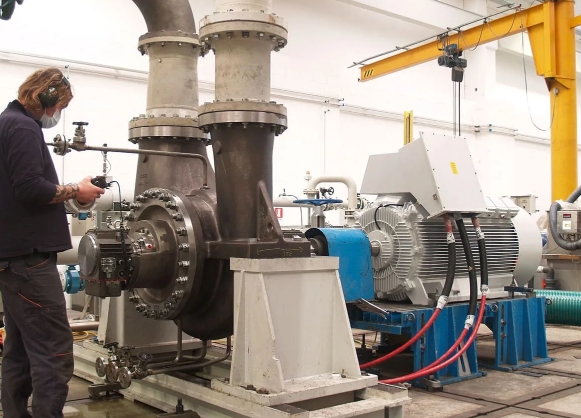

Testing Facilities

Quality Assurance

Our manufacturing units and offices adhere to the latest international standards:

WPIL offers a world class pump testing facility, one of the largest in Asia, servicing all types of pumps and pump packages. The six advanced test beds are equipped to replicate the operating conditions anticipated at each site, with experienced personnel performing measurements using certified digital instrumentation. Tests are performed with project or test bench motors fed by direct-on-line, low and medium voltage frequency converters, or project diesel engines.

- ISO 9001 QMS: Certified for quality management systems, ensuring consistent product and service quality.

- ISO 14001: Committed to environmental management, minimizing our ecological footprint.

- ISO 45001: Dedicated to occupational health and safety, prioritizing a safe and healthy work environment for our employees.